- Review

- Open access

- Published:

Current status of solid-state single crystal growth

BMC Materials volume 2, Article number: 2 (2020)

Abstract

Fabrication of single crystals has long been limited to melt- and solution-growth techniques. However, in recent years solid-state single crystal growth (SSCG) has appeared as a promising alternative to the conventional techniques due to its cost-effectiveness and simplicity in terms of processing. Moreover, the SSCG technique has enabled the fabrication of single crystals with complex chemical compositions and even incongruent melting behavior. A recently proposed mechanism of grain boundary migration known as the “mixed control mechanism” and the associated principles of microstructural evolution represent the basis of the SSCG technique. The mixed control mechanism has been successfully used to control the key aspects of the SSCG technique, which are the grain growth and the development of the microstructure during the conversion process of the single crystal from the polycrystalline matrix. This paper explains in brief basis of the mixed control mechanism and the underlying principles of microstructural evolution in polycrystalline materials and provides a comprehensive overview of the most recent research on single crystal materials fabricated via the solid-state single crystal growth technique and their properties.

Introduction

A need for single crystal fabrication

Single crystals are one of the most important groups of materials due to their continuous, uniform, and highly-ordered structure which enables them to possess unique properties. In many aspects, single crystal materials can be found to be advantageous over polycrystalline materials, and many properties which are found in single crystals cannot be replicated in polycrystals [1]. Currently, even with the technological developments of advanced polycrystalline materials which are designed for specific applications, the electrical, optical, thermal, mechanical, and other properties of single crystals still remain superior. For these reasons, it is not surprising that single crystals, and the methods for their fabrication, are a topic of interest among many researchers.

Single crystals have found extensive use in optical, electronic, optoelectronic, and other applications. Specifically, single crystal semiconductors are one of the most widely researched and used materials. These materials have been applied for various electronic and optoelectronic devices and components, such as light-emitting diodes (LEDs), photodetectors, wide-bandgap devices, high-power lasers, consumer electronics, and more [2, 3]. For example, current computer chip production is not possible without high-quality single crystal silicon (Si) wafers [4]. Due to their outstanding optical and electronic properties, single crystals of III–V semiconductors, such as GaAs, GaN, InP, InAs, and others, are an integral part of devices for application in fiber-optic communication, wireless and satellite communication, solid-state lighting, and more [2]. The importance of single crystal alumina, also known as sapphire, as well as yttrium aluminum garnet (YAG), for laser materials has also been demonstrated through numerous applications. Sapphire has been used in the electronics industry both as a passive substrate material and active device (e.g. silicon-on-sapphire); likewise, it is used for rocket domes, optical data storage, radiation detection, LED devices, optical windows, and other applications [5]. On the other hand, YAG single crystals, and especially Nd3+-doped YAG, are known for their important application in solid-state laser devices, such as waveguide lasers [6] and single crystal fibers for high-power lasers [7], as well as scintillation crystals, and others. Piezoelectric single crystal materials, which were initially developed and utilized as transducers for sonar devices and medical ultrasonic diagnostic devices, have also been applied in sensors, actuators, medical transducers, energy harvesters, and more [8, 9]. As it can be seen, single crystal materials are capable of covering a wide variety of applications, which range from scientific- and research-related to daily life.

Another important use of single crystal materials is as substrates for films of different materials; this enables a whole new collection of applications. Single crystals can be used not only as a mechanical support or a surface at which layer or layers of materials are being deposited but can also act as a single crystal seed during epitaxial growth [10], when the deposited film takes on orientation of the substrate, and sometimes even a lattice structure. Likewise, the fabrication of single crystal epitaxial films on various substrates, which are a vital part of a wide range of devices for electronic, optoelectronic, magneto-optic, and many other applications, although very challenging, is an important goal in the thin film industry due to the numerous advantages of single crystal films [11].

As technological development increases, the need for high-quality single crystal materials, both in bulk and in thin films, grows simultaneously. The availability of various single crystal materials has enabled the development of a new generation of electronic, optical, optoelectronic, and other devices. However, growth of high-quality single crystals, with stable and reproducible quality, low defect density, with various chemical compositions and sometimes even extreme thermodynamic properties is still one of the greatest challenges today [12]. Furthermore, techniques which are currently used for growing single crystals experience many processing-related difficulties despite the technological advancements made throughout the years [13]. Therefore, a high demand for various single crystal materials has imposed a need for improving the growth techniques that are currently used as well as developing new, alternative single crystal growth techniques.

Conventional techniques of single crystal growth

Currently, there are three general approaches for the growth of bulk inorganic single crystals: growth from melt, solution and vapor phase.

Growth from melt is the most commonly used method and is based upon the solidification and crystallization of a melted material. The Czochralski and Bridgman methods are the two most utilized melt-growth techniques. The Czochralski method (Cz) is, for example, very important for the production of single crystals for electronic and optical applications, such as silicon and germanium single crystals, as well as some fluoride and oxide single crystals [13]. Single crystal growth from melt allows for the fabrication of large single crystals of excellent quality in a relatively short time when compared to other growth techniques [14]. However, the melt-growth technique shows some disadvantages as well, such as difficulties in maintaining a stable temperature during the crystal growth and in achieving very high melting points for some materials, achieving chemical homogeneity, especially in the case when multiple elements are present in the system, reactivity of the melted material with the crucible, and high costs of production and equipment.

Unlike the melt-growth technique, in which the material is melted first, the solution-growth technique involves the dissolution of the material to be crystallized within a suitable solvent or flux (e.g. PbO, PbF2, Bi2O3, Li2O, Na2O, K2O, KF, P2O5, etc.) [13, 15]. Out of all the solution-growth techniques, high-temperature solution-growth, also known as flux-growth, has been the most utilized technique for the fabrication of single crystals thus far. This technique is especially convenient for materials that incongruently melt or when melt-growth techniques cannot be applied. The main advantage of this technique is that the crystals are grown below their melting temperatures and the growth of the crystal occurs spontaneously through nucleation or crystallization on a seed. On the other hand, the crystal growth rates for the solution-growth method are much slower than that of the melt-growth method and the presence of flux ions is unavoidable in the crystal. Growth of single crystals via the flux method has found many important applications in the production of single crystal materials such as garnets, various laser crystals, including borates, LiNbO3, BaTiO3, BaB2O4, and more complex systems such as Sr1−xBaxNb2O6, Pb1−xBaxNb2O6, and others [13].

Vapor-phase growth is the third method of growing single crystals, although it is more commonly applied to the fabrication of thin single crystals films on substrates than bulk single crystals. The growth of single crystals through the vapor phase can be accomplished via a sublimation process, reaction in the gas phase and transport reaction, such in the case of chemical vapor transport (CVT) and, physical vapor transport (PVT) [16]. Compared to the melt-growth method, the vapor-growth method utilizes lower processing temperatures which result in a significantly higher quality crystal due to avoidance of incorporating impurities, structural and compositional uniformities, and phase transitions. On the other hand, the low growth and transport rates in the vapor to the interface, associated with the low temperature, make this technique less favorable when compared to the other two growth techniques. However, this technique is still used if neither one of the other two techniques is applicable for the growth of single crystals, which is the case in, for example, SiC single crystals [15].

New technique for single crystal fabrication

Another pathway for growing single crystals which has recently received attention within the research community, is through the solid-state conversion of polycrystalline materials to single crystals. This method is based on a phenomenon which can be observed in many systems, known as abnormal grain growth (AGG).

Solid-state single crystal growth was first observed and studied in metals as a possible alternative to very difficult and expensive procedures used to fabricate metal single crystals. Most of the research on single crystal conversion in metals date to the middle of the last century and include the reports on single crystals of Fe, Mo, W, and other metals [17,18,19]. Later on, in the early 1980s, applying the same principles observed in the metal systems, Matsuzawa and Mase [20, 21] performed research on the growth of single crystals from various polycrystalline oxide materials, including ferrites, garnets, and spinels. They demonstrated that single crystal growth using the solid-state conversion approach, which was reserved only for metals at the time, could also be applied to more complex materials’ systems. Furthermore, many issues associated with conventional single crystal growth techniques, such as heating at high temperatures, maintaining compositional uniformity, contamination from the crucibles, etc., were avoided during the solid-state single crystal growth and performed with much lower production costs. In the years that followed, most of the research focus was on BaTiO3 and Pb(Mg1/3Nb2/3)O3‒PbTiO3 systems, however, still in a limited number.

Although it was observed for the first time decades ago, solid-state single crystal growth can still be considered to be a relatively new technique since it did not receive significant attention from the research community until recently once more work had been done. Due to considerable advancements made in nanotechnologies and sintering technology that have enabled the fabrication of high-quality ceramics, interest in solid-state single crystal growth from polycrystals has been renewed. Solid-state single crystal growth has been shown to be an effective and simple technique for obtaining single crystals with lower capital costs associated with production equipment and components, which could potentially allow for the mass production of single crystals for various existing as well as new applications [22]. The technique utilizes conventional sintering equipment, such as simple furnaces, which cost notably less than the equipment for conventional single crystal growth [23]. For comparison, a furnace for Cz growth of sapphires can cost between $400,000 and $1,000,000 [14], while regular furnaces can cost at least an order of magnitude less. Furthermore, the more complex the composition is, the harder it becomes to fabricate a single crystal using the conventional single crystal growth route, due to chemical inhomogeneities, the presence of elements that melt incongruently, volatility of certain elements, and so on. Therefore, solid-state single crystal growth has been found to be promising and applicable to many different systems, especially systems with complex chemical compositions. Net-shape production, when compared to cutting and shaping from the single crystal boules grown conventionally [14], is another advantage in cost-effectiveness of single crystals produced by solid-state growth since it reduces the number of machining steps after the growth process and even allows for growth of more complexly-shaped single crystals.

This review article will provide an overview of the current status of techniques utilized for the solid-state conversion of single crystals (here, solid-state single crystal growth (SSCG) will be used with the same meaning) and the principles behind them, including AGG, boundary migration, and microstructural evolution. Also, recent reports on the solid-state conversion of single crystals in different systems will be summarized and the most important findings highlighted. The review will be concluded with a discussion on some of the biggest challenges of the SSCG technique, followed by a brief summary and a future outlook.

Solid-state conversion of single crystals from polycrystals

In recent years, solid-state single crystal growth (SSCG) has emerged as a promising alternative technique for growth of single crystals through a conversion process in polycrystalline materials. This technique, which offers numerous advantages over conventional single crystal growth techniques, is based on the occurrence of AGG in polycrystals. More precisely, SSCG technique is developed around what is known as a “mixed control mechanism” [24] of grain boundary migration as well as principles of microstructural evolution. The mixed control mechanism can be used as a general guiding principle for suppressing growth and controlling the growth of single crystals from polycrystalline materials, which are the key requirements for SSCG.

In this section, the phenomenon of abnormal grain growth will be briefly explained and discussed. Furthermore, the mixed control mechanism of grain boundary migration and the principles of microstructural evolution will be presented and explained. However, for more details on the mixed control mechanism and the related phenomena, the reader is strongly encouraged to refer to the research articles of Dr. Kang and his associates who developed the mixed control mechanism and have conducted extensive research work in this field.

Abnormal grain growth (AGG)

In general, there are two different types of grain growth which can be observed during sintering. One, known as normal grain growth (NGG), involves a uniform rate of grain growth via thermally activated grain boundary migration which results in a uniformly developed microstructure with respect to the sintering time (stationary grain growth). The other type of grain growth is non-normal grain growth (non-NGG) and instead follows a non-stationary grain growth [23]. AGG is a type of a non-NGG and is referred to as the grain growth where a certain number of grains experience a much faster growth rate than the neighboring grains in the matrix. Such growth may significantly change a grain size distribution, leading to broadening or even a bimodal grain size distribution. With extended annealing time, the abnormal grains gradually increase in size by consuming the surrounding matrix grains until they impinge upon each other. This lowers the driving force for further growth of abnormal grains and they usually stop growing at this stage [25].

In general, AGG is a phenomenon which is not favorable during materials processing since the presence of abnormally grown grains may have a negative effect on microstructure development, and therefore on the physical properties of materials. The appearance of AGG has been observed in many different systems both ceramic and metallic. Many authors have tried to explain the occurrence of AGG, suggesting different mechanisms and models, however, the underlying reasons for AGG are still under debate [26]. Generally, the following phenomena have been suggested as the possible causes of AGG: (a) the presence of second phases, pores or impurities (b) high anisotropy of the interfacial energy and grain boundary mobility, and (c) the presence of a thin liquid film at the grain boundary which facilitates grain boundary mobility [23, 24]. As explained in [23], in all of the aforementioned phenomena, it was originally thought that AGG was a result of atomic diffusion across the grain boundary. However, neither of these models could explain, nor be entirely applied to all of the systems which were studied thus far. Therefore, another explanation or model was necessary to more clearly explain the phenomenon of AGG.

Recently, a “mixed control mechanism” was proposed to explain AGG and other types of grain growth behavior; this further enabled the definition of the principles of evolution of the microstructure in polycrystalline materials [23, 27].

Mixed control mechanism

The classical understanding of the mechanisms of AGG, which were mentioned in the previous section, provide explanation for grain boundary migration which is based on atomistic diffusion. These models, however, can only be applied to some specific cases; for this reason, the mixed control mechanism, which is a more universal model, was suggested to explain different grain growth behaviors. The mixed control mechanism has its roots in the theories of crystal growth and experimental observations and explains the phenomenon of grain boundary migration considering the atomic structure of grain boundaries; this has not been taken into account in classical grain growth theory [24].

There are two different types of grain boundaries which can be identified by differences in structure. One is a rough (round) grain boundary which exhibits an atomically disordered structure, and the other is faceted grain boundary, whose interface is smooth and atomically ordered. In some recent studies [27,28,29,30,31], it was observed that the type of grain boundary has the most significant influence on the occurrence of AGG. While rough grain boundaries were observed to result in NGG, faceted grain boundaries were more likely to undergo AGG (or some other non-normal type of grain growth) [24, 32]. In other words, the presence of faceted grain boundaries in the system can be regarded as a prerequisite for AGG. Such a phenomenon was explained by differences in the grain boundary mobilities of rough and faceted boundaries with regard to the driving force for grain boundary migration [33].

In the case of rough interfaces, grain boundary migration has been shown to have a direct relationship with respect to the driving force for the grain growth. Because of their atomically disordered structures, rough interfaces allow for a large number of attachment sites for atoms, which then enables a high rate of interfacial reactions. Since the migration kinetics are governed by the slowest process, in the case of rough grains, the diffusion, as the slowest process, will be the rate-determining process for grain boundary migration [26]. On the other hand, for faceted grains, the experimental results have shown that the grain growth is controlled by either interface reaction (attachment of atoms from one grain to an adjacent grain) or atomic diffusion across the grain boundary, depending on which process is slower. Furthermore, it has been demonstrated that there is a relationship between the grain boundary migration of faceted interfaces and the driving force being non-linear [33,34,35].

Each individual grain in the polycrystalline matrix possesses its own driving force for grain boundary migration and the maximum driving force for grain growth (Δgmax) is defined by the average grain size and grain size distribution [24]. In addition, the maximum driving force is assigned to largest grain in the grain population and increases with decreasing average grain size as well as broadening of the grain size distribution [27]. Another important parameter in grain growth is the critical driving force (Δgc) for grain growth which depends mainly on the type of grain boundary interface and can be changed by varying the temperature, atmosphere, oxygen partial pressure, and presence of dopants [24, 28,29,30].

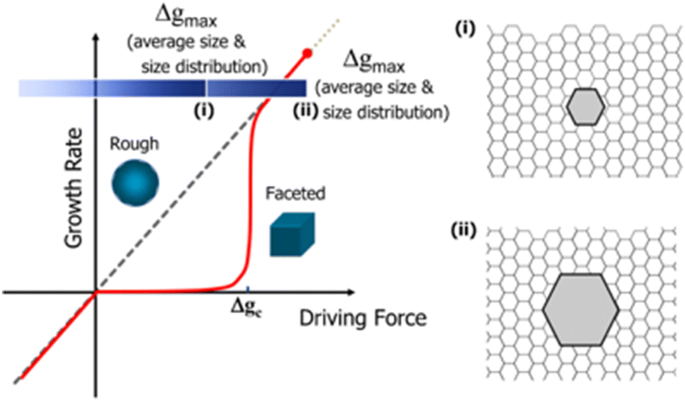

According to Kang et al. [24], the ratio between Δgmax and Δgc determines the type of the grain growth and can even help to further predict and explain the microstructure development. Additionally, the authors explained that there are, in general, four different grain growth behaviors which can be observed depending on the magnitude of Δgmax and Δgc and their relation [24, 36]:

- 1.

Normal grain growth (NGG), which is a stationary grain growth for which Δgc = 0 (presented with a dashed line in Fig. 1).

Fig. 1 Schematic illustration of the mixed control mechanism of grain growth: (left) Mixed control mechanism of grain growth for grains with rough and faceted grain boundaries; (right) Schematic of two systems with different microstructures due to the difference in Δgmax [24]

- 2.

Pseudo-normal grain growth, when 0 < Δgc ≪ Δgmax.

- 3.

Abnormal grain growth (AGG) occurs when Δgc≤ Δgmax.

- 4.

Stagnant grain growth (SGG) occurs when Δgmax ≪ Δgc.

In systems with faceted grain boundaries, the growth of faceted grains is governed by the diffusion process when the driving force for growth is larger than the critical driving force. On the other hand, when the driving force is smaller than the critical, the growth rate is significantly smaller than that by diffusion and is led by the interface reaction instead [32]. Such non-linear grain growth behavior with respect to the driving force is therefore said to be mixed controlled by either a diffusion or interface reaction, as illustrated in Fig. 1.

AGG, which is the focus of the SSCG method, occurs in systems with faceted grain boundaries. For an efficient solid-state single crystal conversion, it is preferred that the growth of grains within a polycrystalline matrix be negligible (with Δgmax lower than Δgc), while the growth of one or a small number of grains (acting as single crystal seeds) is promoted. For the latter case, the driving force should be larger than the critical driving force (Δgc) in order for the grains to begin experiencing AGG. For such growth conditions, and in order for single crystal conversion to occur, it is necessary to have a well-balanced ratio between Δgmax and Δgc [23]. The average grain size and grain size distribution significantly impact Δgmax and, as a consequence, the ratio between the maximum and the critical driving force, as shown in Fig. 1. Similarly, a variation in Δgc, affected by the change in the grain boundary structure, will also impact the microstructural development.

The predictions set by the mixed control mechanism on microstructural evolution can be demonstrated best by observing the effects of a change in Δgmax under constant Δgc, or vice versa. For example, in the experiments of Jung et al. [37], when Δgc was kept constant, Δgmax could be manipulated by changing the initial particle size of the powder sample. As a result, the fine-grained BaTiO3 sample exhibited AGG, while the same sample, but with coarser particles, underwent SGG due to differences in Δgmax. Such an observation confirms the predictions presented in Fig. 1. Conversely, when Δgc was varied, different scenarios could be observed depending on which parameter was affecting the grain boundary structure. A relationship between the change in oxygen partial pressure and the degree of faceting of grain boundaries is one of the best examples of how this parameter can affect the grain boundary structure and therefore lead to AGG; several studies conducted in which BaTiO3 was used as a model system support this [28, 29, 37]. Other parameters that can affect the grain boundary structure (e.g. doping, temperature and sintering atmosphere) have also been investigated [28, 30, 33, 38, 39], and can be seen as an additional endorsement to the concept of the mixed control mechanism.

Furthermore, some experimental studies have confirmed that even different crystallographic directions will experience differences in migration kinetics in systems with faceted grain boundaries [33, 35, 40]. Under some experimental conditions, the migration in certain crystallographic directions was even completely omitted [35]. According to the authors of the studies, the presence of the critical driving force for grain boundary migration, Δgc, which varied with crystallographic planes, was the reason for this discrepancy in results. Such observations are consistent with the assumptions of the mixed control mechanism and are further evidence that the microstructural development in the systems with faceted grain boundaries is a result of the non-linear relationship between the grain boundary migration and the driving force for migration.

SSCG technique

Despite the fact that abnormal grain growth was found to be an unwanted event during sintering, the SSCG technique was actually based on this phenomenon [41]. Furthermore, the SSCG technique was developed as a direct application of the principles of microstructural evolution which further supported the understanding of the mixed control mechanism [24].

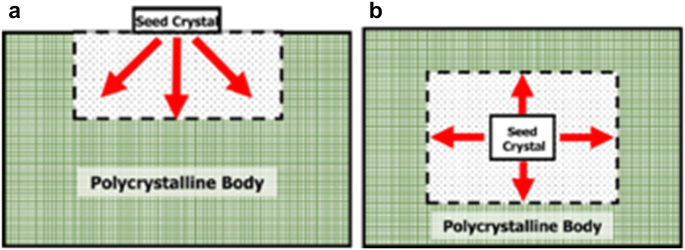

In most practical cases, the SSCG technique uses a single crystal seed of a similar crystalline structure with the matrix material which is either embedded in the polycrystalline green body or placed on top of it, as illustrated in Fig. 2 [23]; this technique is known in the literature as the seeding method. The seed and the green body are both sintered at a temperature which is below the melting point of the crystal. This enables the formation (or conversion) of the single crystal material from the polycrystals through a controlled AGG process as well as in the crystallographic direction of the seed crystal. Figure 3 depicts the process of conversion where the small matrix grains are being consumed by a large single crystal seed. The same principle is used for the fabrication of single crystals from melt, except in this case, heating well above the melting temperature is necessary and, also, other issues associated with this processing method are difficult to avoid. Furthermore, single crystals can be grown using the “seed-free method” via prior nucleation of the seed crystal in the polycrystalline matrix by applying a temperature gradient or by adding a dopant material [23]. This method does not require embedding of the single crystal seed in the polycrystalline matrix as in the case of the seeding method, but the principle of the single crystal conversion is the same.

Schematic of the solid-state conversion of single crystal: a Seeding from the top side of the polycrystalline material; b embedding of the seed crystal [23]

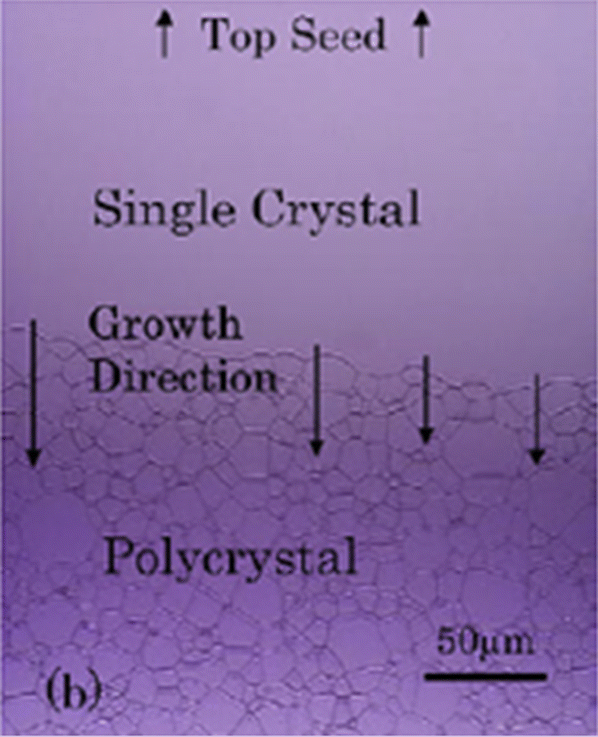

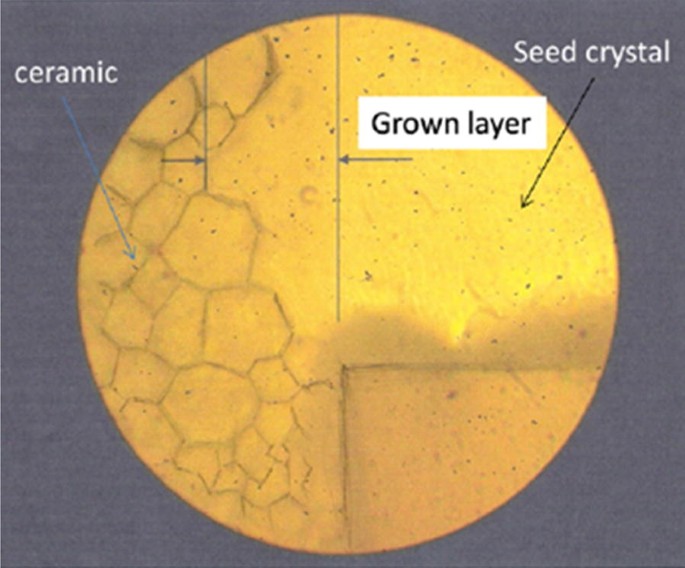

Cross-section of the Nd:YAG single crystal grown by SSCG method [42]

Although the SSCG method has given very good results thus far, there are still certain aspects which need to be considered and which could be limiting, such as the choice of the seed crystal, density of polycrystalline matrix, size distribution of the grains, structural matching between the seed crystal and matrix, and control of the interface [41]. So far, the SSCG has been successfully applied to only a limited number of systems which mainly include oxides and piezoelectric ceramic materials.

The following section of this paper will provide an overview of the results which have been reported on single crystal growth via the SSCG technique.

Current developments on solid-state single crystal growth

Pb-based piezoelectric materials

Solid-state conversion of single crystals has recently been proved to be a very successful way to produce piezoelectric single crystals for commercial usage. For example, single crystals such as Pb(Mg1/3Nb2/3)O3–PbTiO3 (PMN–PT) and Pb(Mg1/3Nb2/3)O3–Pb(Zr,Ti)O3 (PMN–PZT) are now produced by the SSCG method, while the conventional methods include growth via Bridgman or flux methods. By using the flux-method, it is difficult to obtain single crystals of size and quality required for the commercial usage. Another issue associated with this method is that it causes vaporization of the toxic PbO substance. With the Bridgman method it is hard, on the other hand, to achieve compositional uniformity within the growing crystal. The SSCG technique, therefore, has appeared as a very promising and effective method for production of lead-based piezoelectrics.

PMN–PT

Single crystals of some relaxor-based ferroelectrics, such as Pb(Mg1/3Nb2/3)O3–PbTiO3 (PMN–PT) exhibit superior properties compared to polycrystalline forms of the same composition. Especially important are PMN–PT materials with 35 mol% of PbTiO3 added because of their potential application as electromechanical devices. A possibility to grow a single crystalline PMN–PT material by the SSCG method was recognized many years ago. In 1998, Li et al. [43] used a method of embedding a PbTiO3 (PT) single crystal into polycrystalline Pb(Mg1/3Nb2/3)O3 (PMN), to grow PMN–PT single crystals. A powder with a single crystal was cold isostatically pressed and then sintered and annealed under pressureless conditions in a range of temperatures. The authors were able to observe distinct boundaries between the grown single crystal area and polycrystal grains of matrix material. Khan et al. [44] reported a solid-state growth of the PMN–35 mol% PT single crystal using the same method which the previously mentioned group of authors used in their study. During preparation of the matrix material, a specific amount of PbO was mixed in. Following the sintering of PMN with the PT single crystal embedded in the material, the compact was annealed at 1150 °C for 10 h. During annealing, PbO was in a liquid phase, which, according to the authors, had a significant impact on the single crystal growth inside the polycrystalline matrix. The authors also showed that as the single crystal boundary migrated through the polycrystalline matrix, PbO as the second phase accumulated at the triple points in the matrix and remained entrapped in a form of spherical inclusions in the grown crystal.

In 2003, another group of authors reported [45] a study on the same material which included seeding of the PT single crystal in the PMN matrix with a small amount of liquid PbO, added to the matrix to increase the grain boundary mobility. In this study, the authors used a vacuum hot-pressing furnace following cold isostatic pressing of the green pellets to obtain the compact. They observed a clear boundary between the single crystal and polycrystal area. But what is more important, they observed a notable difference between the samples in which the liquid PbO was not added and when it was included in the matrix. A small amount of the liquid PbO increased the single crystal growth constant by nearly 100 times.

A common issue which was observed in all the previously mentioned studies was that the grown single crystals contained a significant number of pores as well as a PbO second phase entrapped inside the structure. This negatively affected the properties of the single crystals. An interesting observation made by Kim [45] was that the single crystal seed orientation had a great influence on the elimination of the PbO liquid phase from the grown single crystal.

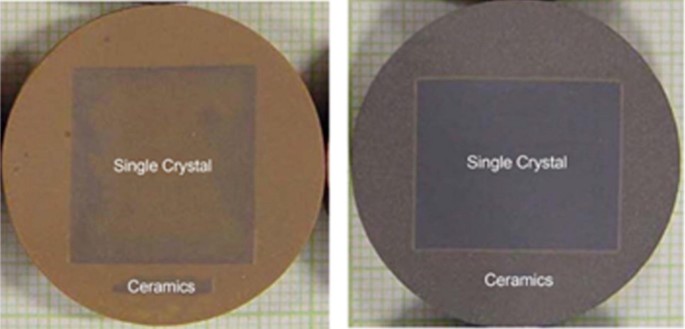

Despite the issues related with the growth of PMN–PT single crystals in laboratory conditions, this type of material was successfully fabricated by scaling-up the SSCG process for commercial purposes. It is interesting to mention that by the SSCG method, it is possible to grow both undoped and doped (e.g. Fe, Mn) PMN–PT single crystals with very high quality and excellent dielectric and piezoelectric properties [47]. Recently, growth of undoped and Mn-doped 71PMN–29PT high-quality single crystals using the SSCG method were reported [46], in which excellent piezoelectric and electromechanical properties of both single crystals were demonstrated. With such results, these materials, and especially Mn-doped single crystal, could be utilized as high-power piezoelectric transducers in sonars and medical devices. In this study, undoped and Mn-doped (Mn–PMN–PT) PMN–PT single crystals were fabricated by Ceracomp Co., Ltd. from South Korea (Fig. 4), which has become well-known for their production of high-quality piezoelectric single crystals via the SSCG method. In another study, Mn–PMN–PT single crystals were grown into very thin plates (< 0.2 mm) which enabled them to show high stability and piezoelectric performance which is suitable for high frequency composites, medical ultrasound probes, non-destructive testing devices, and flexible devices applications [9].

Polished surfaces of 71PMN–29PT single crystals grown by SSCG method: (left) undoped and (right) Mn-doped [46]

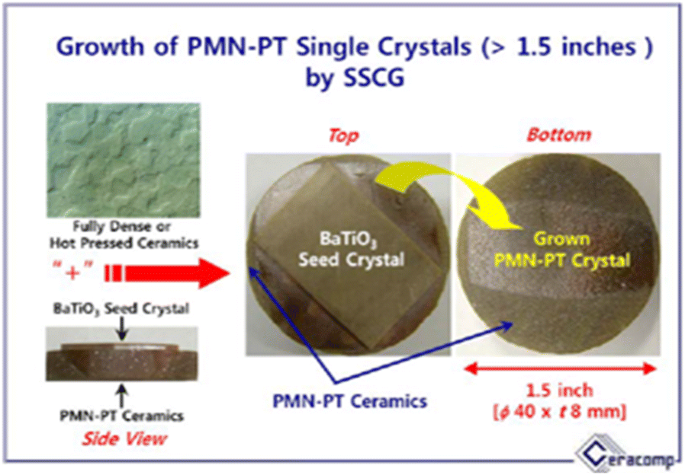

Company Ceracomp Co. also introduced a method for obtaining PMN–PT single crystal ceramics by seeding with a BaTiO3 single crystal. Figure 5 presents a schematic for obtaining such materials via the SSCG method. First, they prepared a PMN–PT ceramic using a hot-pressing furnace, after which they placed a BaTiO3 single crystal on top of the ceramic and heat-treated the sample [48]. Using this process, they were able to fabricate a homogeneous and fully dense PMN–PT single crystal. Hot-pressing of the ceramic compact was found to be very beneficial for obtaining a high-density product at the end.

Schematic of experimental procedure for fabrication of PMN–PT single crystals by SSCG method [48]

Lim et al. [49] published their investigation on a ternary system comprised of BiScO3–Pb(Mg1/3Nb2/3)O3–PbTiO3 (BS–PMN–PT) in which they grew a single crystalline BS–PMN–PT via the SSCG method which included embedding of the single crystal Ba(Zr,Ti)O3 (BZT) into the matrix compact. The authors used four different fluxes (Bi2O3, LiBiO2, PbO/LiBiO2 and PbO/Bi2O3) in which they tried to grow single crystal BS–PMN–PT. The fluxes were added with the intention of enhancing the material transfer by forming a liquid phase during sintering. What they observed was that the PbO/Bi2O3 flux enabled growth of the BS–PMN–PT single crystal from BZT single crystal, while other fluxes were inefficient, which indicated that the BZT single crystal was chemically stable against the PbO/Bi2O3 flux.

PMN–PZT

Along with the PMN–PT single crystal relaxor ferroelectric, Pb(Mg1/3Nb2/3)O3–PbZrO3–PbTiO3 ternary system, or shorter Pb(Mg1/3Nb2/3)O3–Pb(Zr,Ti)O3 (PMN–PZT), is a very important material which has numerous applications in areas such as ultrasonic transducers and actuators due to its large piezoelectric coefficient and high electromechanical coupling factors in areas such as medical. Traditionally, these types of single crystal materials were grown via the flux method or the Bridgman method which were found to be costly and usually resulting in chemical inhomogeneity of the grown crystals. Zhang et al. [50] demonstrated single crystal growth of PMN–PZT by means of the SSCG technique. The matrix compact containing Pb3O4, MgNb2O6, ZrO2, and TiO2 was prepared by mixing and pressing of the raw materials into pellets, sintering in the range from 1100 to 1200 °C, followed by hot isostatic pressing of the ceramics. BZT single crystal plates were used as seed crystals for single crystal growth during the SSCG process. The density of such obtained PMN–PZT single crystals was found to be greater than 99% of the theoretical density. The authors further investigated the electromechanical and piezoelectric properties of the fabricated PMN–PZT single crystals and showed that single crystals grown by the SSCG method exhibited properties which were greater than the previously investigated PMN–PT single crystals.

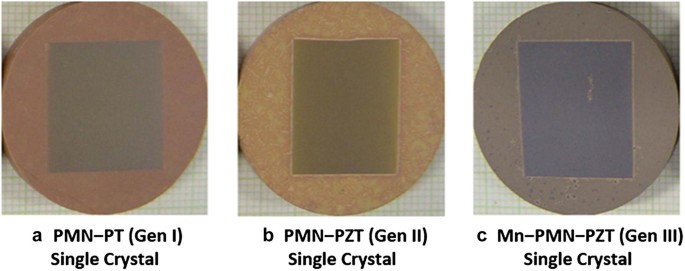

Further investigation on PMN–PZT single crystals obtained by the SSCG method was extended to doping of the same with manganese (Mn), iron (Fe), or even indium (In). In 2017, researchers from the Sunmoon University in South Korea, in collaboration with the Ceracomp Co., presented their study in which they doped single crystal PMN–PZT with Mn [8]. In this study, the authors used three different generations of piezoelectric single crystal materials (PMN–PT - first, PMN–PZT - second, and Mn-doped PMN–PZT - third generation) obtained by the SSCG method in order to compare the properties of each to one another. The preparation of the single crystals included attachment of the BZT single crystal as a seed crystal, after primary sintering. By applying the SSCG method they were able to obtain high-quality single crystals (Fig. 6) which exhibited good piezoelectric properties, among which Mn-doped PMN–PZT was shown to be the most promising.

Three generations of piezoelectric single crystals grown by the SSCG method [8]

Until now, the SSCG technique was shown to be the only method to produce large relaxor-PZT single crystals, such as PMN–PZT, of different ratios of Pb(Mg1/3Nb2/3)O3 (PMN), PbZrO3 (PZ) and PbTiO3 (PT). The change of PMN/PZ/PT ratios has a significant influence on materials’ piezoelectric and dielectric properties [47]. Also, because of the PZ component in the PMN–PZT system, which exhibits incongruent melting behavior, and PbO which is very volatile, PMN–PZT single crystal has been successfully produced only by the SSCG technique so far.

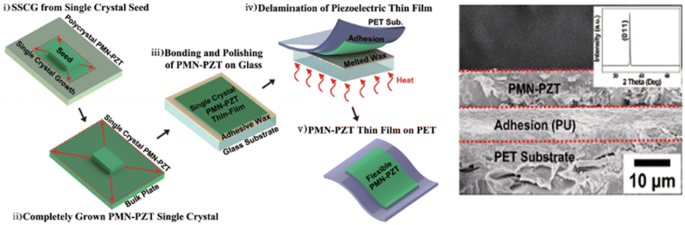

An interesting report which was done by Hwang et al. [22] in 2015 demonstrated the possibility of fabricating thin film PMN–PZT single crystals by the SSCG method used for the fabrication of a high-performance energy harvester material. The authors used a BZT single crystal seed plate to attach it to the surface of the polycrystalline ceramic during the SSCG process. Afterwards, they were able to take the thin single crystal PMN–PZT film from the glass substrate and transfer it to the plastic substrate without making any damage to the material. A schematic illustration of the whole process is presented in Fig. 7.

Flexible PMN–PZT thin film single crystal energy harvester: (left) schematic illustration of the SSCG process of fabrication; (right) scanning electron microscope (SEM) micrograph of the cross-section of PMN–PZT single crystal film on plastic substrate [22]

Pb-free piezoelectric materials

Conventionally, piezoelectric single crystals have been produced via the flux or the Bridgman method. As previously mentioned, these methods require high-temperature treatment for the melting of the raw materials which can, at the end, create chemical inhomogeneity and, more importantly, evaporation of highly toxic substances, such as lead. In the last few decades, the question of environmental and health issues concerning the production of the lead-based piezoelectric single crystal materials has been raised. As the growing market demand for these materials is rising more and more each year, a development of lead-free piezoelectric ceramics and single crystals which will be able to replace lead-based piezoelectric materials became necessary.

This paper will review the two most studied lead-free piezoelectric ceramic materials which were proven to be able to be fabricated by the SSCG technique. The two lead-free piezoelectric materials which will be presented here belong to the KNaNbO3 (KNN) lead-free family and the (Na1/2Bi1/2)TiO3–BaTiO3–(K1/2Na1/2)NbO3 (NBT–BT–KNN) family of single crystals.

KNN-based lead-free single crystals

KNaNbO3 (KNN), a lead-free piezoelectric material has attracted a lot of attention in the past decade because of its desirable properties as a piezoelectric and dielectric, and a potential to replace lead-based piezoelectric ceramics and single crystals. KNN has a perovskite structure and exhibits three phase transitions, at around 160 °C from rhombohedral to orthorhombic phase, at around 200 °C from orthorhombic to tetragonal phase, and at 420 °C from tetragonal to cubic phase [51]. Of importance regarding this material is that it undergoes AGG during sintering after the temperature reaches a certain critical point, which in turn decreases its piezoelectric properties. On the other hand, such behavior is important in terms of the growth of the single crystal material by the SSCG method.

Two different approaches have been recognized so far which can be used for the fabrication of single crystalline KNN by the SSCG method. One approach utilizes growth of the single crystal by the seeding method and the other can be referred to as the “seed-free” method for the growth of single crystals.

KNN-based single crystals grown by seeding method

In the study conducted on obtaining single crystal KNN via the SSCG method, Fisher et al. [52] used a <110> KTaO3 single crystal as a seed crystal which was found similar to KNN in terms of the unit cell parameters. The single crystal was embedded into the powder matrix and, following this, the green body was prepared by uniaxial pressing and subsequent cold isostatic pressing. The authors’ goal was to investigate the influence of the applied pressure on the quality and porosity of the grown KNN single crystal. They determined that certain loading pressures had significant impacts on the porosity of the grown single crystals. The single crystal obtained by heat treatment under applied pressure in a hot pressing furnace in comparison to the sample heat-treated under pressureless conditions experienced a much smaller number and size of the pores, demonstrating the crucial role of pressure in obtaining a high-density single crystal KNN. The SEM images presented in Fig. 8 depict interfaces between single crystal seed and grown single crystal, and grown single crystal and the polycrystalline matrix in the samples prepared in pressureless and pressure-assisted conditions.

SEM images of KNN single crystal grown by SSCG method in: a, b conventional furnace, and c, d hot pressing furnace [52]

Benčan et al. [53] investigated the single crystal growth of KNN and Li, Ta-doped KNN by the SSCG method. Their preparation method for the green compacts was similar to the work of Fisher et al. They also used KTaO3 as a seed crystal due to its compatibility with KNN. The authors demonstrated that the single crystal growth in the hot press furnace is advantageous over the conventional furnace. They explained that in the conventional furnace, the growth of single crystal, matrix grains, and densification are all happening simultaneously, which might be a reason for the high number of pores left trapped inside the single crystal. Another point they made was on the influence of the addition of the sintering aid (in their case, K4CuNb8O23) on single crystal growth. The sintering aid was shown to be helpful when 2 mol% was added because it allowed the growth of the matrix grains to some extent, after which the driving force for the single crystal remained constant, allowing the crystal to grow under extended annealing time. On the other hand, a smaller amount of sintering aid (0.5 mol%) was found to cause a reduction of the single crystal and matrix grain growth rates.

Similarly, Yang et al. [54] studied the single crystal growth mechanism by the SSCG method on a KNN-based piezoelectric material doped with lithium. Sintering of the matrix material with a buried single crystal seed of KTaO3 was performed in the presence of a sintering aid, MnO2. The results demonstrated that the addition of the sintering aid created a liquid phase which resulted in interfacial reactions that significantly affected the crystal growth rate, but only up to a certain threshold. Also, the authors observed a high number of pores, which is the result of the fast movement of the interface between the growing single crystal and matrix grains which tend to increase in size as the growth of the crystal continues [54].

Although the SSCG method was found promising for growth of the lead-free piezoelectric single crystals, one of the biggest problems associated with this method is in the high porosity of the end product. Uwiragiye et al. [51] reported in their study on 0.96(K0.48Na0.52)NbO3–0.03(Bi0.5(Na0.7K0.2Li0.1)0.5)ZrO3–0.01(Bi0.5Na0.5)TiO3 in which they used a KTaO3 seed crystal with <110> orientation, that the piezoelectric properties of the grown single crystal could be enhanced if the porosity of the crystal could be reduced. They observed that the porosity increases with distance from the seed crystals and that the pores are irregular in both shape and size.

KNN-based single crystals grown by seed-free method

Using a single crystal seed to instigate conversion of the polycrystalline matrix grains to a single crystal with a desired crystallographic direction can be achieved by the SSCG method. However, despite the difficulties associated with controlling the growth process, the quality of the grown crystal is also affected by the seed crystal. Therefore, a seed-free method of growing single crystals by the SSCG method has been proposed. This method is known as the seed-free solid-state single crystal growth, or SFSSCG.

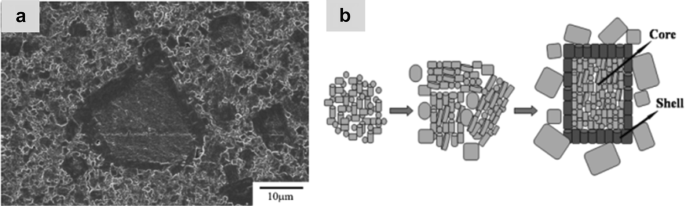

In 2007, Zhen and Li reported their study on growth of single crystals in KNN and (Li0.04K0.44Na0.52)(Nb0.85Ta0.15)O3 (LKNNT) ceramic materials prepared and sintered in a conventional way, without seed crystals [55]. The authors were able to observe a small number of coarse grains which experienced AGG in both samples. While the distribution of these grains was somewhat random in KNN, the distribution of grains in LKNNT was more ordered. An interesting phenomenon which the authors observed was that the abnormal grains had a core–shell structure, as can be seen in Fig. 9a. Different structural features of the core and shell grains could be observed, but both regions showed to belong to a single crystal grain. Another interesting observation was how the core grains maintained their original grain size; this could not be explained using classical grain growth theory. The authors proposed a schematic explanation for the core–shell structure formation (Fig. 9b). But despite the AGG, the ceramic materials exhibited good piezoelectric and dielectric properties, showing that the SFSSCG method could be a promising technique for the single crystal growth.

A core–shell structure in KNN: a SEM micrograph; b schematic diagram showing procedure for formation of the core–shell structure [55]

Following Zhen and Li, many other authors reported successful fabrication of KNN-based single crystals through the SFSSCG method. In 2010, Wang et al. [56] reported single crystal growth of KNN by utilizing the AGG mechanism. The authors used a sol-gel route for the powder preparation, and they were able to grow single crystals of KNN as big as 3 mm by sintering for 2 h at 950 °C.

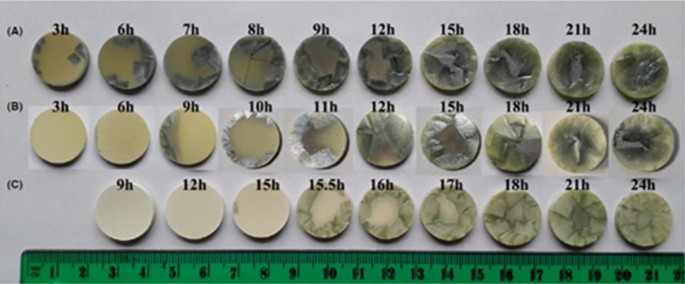

Later on, Jiang et al. [57] showed in their study on KNN that it is possible to obtain a high-quality single crystal KNN of perovskite structure (11 × 9 × 3) mm3 via the SFSSCG method through a relatively simple and low cost route. They observed that single crystal grains tend to form a structure with a self-assembled arrangement, with preferred orientation and layer stacking along the growth direction. They also performed a systematic study on the effects of sintering aid content (LiBiO3), as well as sintering time and temperature on crystal growth. Figure 10 presents the results of their systematical study on crystal growth kinetics, where the growth of large grains was triggered under certain conditions. In the same year, Ahn et al. [58] reported self-growth of a centimeter-sized single crystal of 0.985(K1/2Na1/2)NbO3–0.015Ba(Cu1/3Nb2/3)O3 (KNN–BCuN) by the SFSSCG method. The authors prepared a KNN polycrystalline powder in a conventional way, with the addition of Ba2+ ions aimed to compensate for the loss of Na+ ions due to Na2O volatilization during the liquid phase sintering, and CuO as sintering aid which is known to form a liquid phase at high temperatures. The authors were able to observe the self-growth of giant grains which were single crystals, as shown in Fig. 11. They also stressed the importance of the CuO addition because it had a vital role in the stimulation of AGG. Although the giant single crystal of KNN–BCuN contained a significant number of pores, it showed excellent piezoelectric properties and was found to be a promising candidate for piezoelectric sensors and energy harvesting devices. Another important benefit presented by the authors was that the SFSSCG method was approximately 100 times faster than the SSCG method.

KNN samples with LiBiO3 sintering aid, sintered under different temperature and time regimes [57]

Variation of sizes of KNN–BCuN single crystals with sintering temperature grown by seed-free SSCG method [58]

In the years following, there have been many different reports on single crystal growth in KNN-based ceramics by using the SFSSCG method in which the authors achieved improvements in piezoelectric properties of the grown crystals. Yang et al. [59] reported improved piezoelectric properties in their self-grown single crystal of (K0.45Na0.55)0.96Li0.04NbO3. Another group reported CaZrO3-doped KNN-based single crystals [60] grown by the SFSSCG method, which showed improved piezoelectric and dielectric properties as well. In 2017, Hao et al. [61] reported their study on the effects of different ratios of sodium and potassium in KNN on the growth of the single crystal by the SFSSCG method. They summarized their results in a composition-temperature phase diagram at which they showed that the growth of the single crystal KNN is possible only in a very narrow range of Na/K ratios and temperatures.

In the most recent study, the group of authors who had already reported their study on KNN–BCuN ceramics [58], has now proposed a compositional design rule for the growth of large single crystals in KNN-based ceramics by the SFSSCG method [62]. They determined that the amount of Ba2+ (donor ion) in the system had a significant role in AGG, and therefore on the growth of the single crystal. The authors came up with equations with which they were able to calculate, and in that way predict, how much of each ion is present or substituted in the system. Their calculations showed a good fit with the experimental data, so they were able to establish a rule for the design of the KNN-based single crystals based on their equations.

Later on, Jiang et al. [41] proposed a crystal growth method in their latest work which could qualitatively explain the SFSSCG mechanism in KNN-based ceramics. As they pointed out, the AGG at which the SFSSCG model is based on should no longer be regarded as abnormal, but normal since the process of grain growth is now understood much better, and in that way better controlled, at least in case of KNN-based materials.

NBT-based lead-free single crystals

Another group of promising lead-free piezoelectric ceramics which were found to be able to be converted to single crystal materials are (Na1/2Bi1/2)TiO3 or NBT-based materials. These materials may be presented with a general formula (Na1/2Bi1/2)TiO3–BaTiO3–(K1/2Na1/2)NbO3 or shorter NBT–BT–KNN. NBT–BT–KNN single crystals are traditionally fabricated via the flux or the Bridgman method, but both methods introduce the difficulties of getting the crystals to have uniform chemical compositions due to the volatility of Na- and Bi-oxides. This further creates difficulties in obtaining single crystalline NBT–BT–KNN with desired piezoelectric properties. The SSCG method, therefore, appeared as a promising technique for obtaining such single crystal materials.

In one of the earliest reported studies on the application of the SSCG method for the conversion of polycrystalline NBT‒BT‒KNN to single crystal, Park et al. [63] successfully grew an NBT–BT–KNN single crystal from conventionally prepared ceramic powder. In their experimental work, this group used a SrTiO3 single crystal seed of <110> orientation embedded in a ceramic powder to initiate single crystal growth during a 50-h annealing period at a temperature of 800 °C. The grown single crystal exhibited good piezoelectric properties which were comparable to those of other lead-free single crystals. The same group of authors continued their research on the same material [64] and 2 years later reported their finding that the KNN content in NBT–BT–KNN had a significant effect on the piezoelectric properties of NBT–BT–KNN single crystals. Along with that, they were able to demonstrate that the SSCG method was a prospective method for growth of NBT–BT–KNN single crystals with high performance, which could replace Pb(Zr,Ti)O3 for actuator applications. In the same year, the aforementioned group of authors presented their results on NBT–BT–KNN single crystals by seeding with a SrTiO3 single crystal [65]. They fabricated a highly dense NBT–BT–KNN single crystal with significant improvements in its piezoelectric properties, which were higher than that of any previously reported ceramics or single crystal. The high relative density (96.6%) of a grown crystal was achieved by creating a layered structure which was composed of pre-sintered ceramic pellets between which a seed crystal was positioned, followed by a 30-h annealing period at 900 °C in air. This method enabled the authors to fabricate a single crystal which had a notably smaller number of pores, which typically remain entrapped in the powder compact.

Another group of NBT-based piezoelectric single crystals which will be covered by this review pertains to the solid solution of (Na1/2Bi1/2)TiO3 (NBT) with alkali earth perovskite-type materials (CaTiO3, SrTiO3 and BaTiO3).

The solid solution system (Na1/2Bi1/2)TiO3–BaTiO3 (NBT–BT) was found to be a promising environmentally friendly, lead-free piezoelectric material. In the study on NBT–BT single crystals obtained by the SSCG method, Moon et al. [66] demonstrated that the common problem associated with the insufficient AGG, which is important for the growth of single crystals of practical sizes, can be overcome. They fabricated NBT–BT single crystals by using a SrTiO3 seed crystal embedded in the ceramic powder compact, which had a certain degree of porosity and density inhomogeneity, but still exhibited good piezoelectric properties. In 2016, Gürbüz et al. [67] reported their comparative study between NBT–BT single crystals grown by SSCG, which included both the conventional and spark plasma sintering (SPS) methods. The authors demonstrated a significant difference in porosity between the single crystals obtained using these two sintering techniques. They achieved 99% of the theoretical density of the grown single crystal for the sample sintered by SPS for 5 min at 950 °C, while conventional sintering in air for 2 h at 1130 °C produced a single crystal with 96% of the relative density. The same result was in favor to SPS sintering when the dielectric properties were measured, which demonstrated that SPS might be an efficient technique for fabrication of NBT-based single crystals by the SSCG method, providing high relative densities and low alkaline evaporation.

In literature, reports can also be found on NBT-based single crystals grown by the SSCG technique which used other alkali earth perovskites, such as CaTiO3 and SrTiO3. For example, in 2016, Lee et al. [68] reported for the first time a single crystal 0.8(Na1/2Bi1/2)TiO3–0.2SrTiO3 grown by the SSCG method, which was grown from the SrTiO3 single crystal as a seed crystal. The grown single crystal exhibited high porosity. Le et al. [69] afterward reported growth of 0.75(Na1/2Bi1/2)TiO3–0.25SrTiO3 single crystal using the same approach. They investigated the dependence of growth of the single crystal and matrix grains on sintering time and temperature, and showed that the results could be explained with the mixed control mechanism of microstructural evolution [23].

Later on and for the first time ever, a different group of authors reported on a fabricated 0.96(Na1/2Bi1/2)TiO3–0.04CaTiO3 single crystal [70] via conversion of the polycrystalline powder matrix to a single crystal, in presence of SrTiO3 as a seed crystal. The grown single crystal showed improved ferroelectric and piezoelectric properties compared to its polycrystalline ceramic counterpart.

Ferroelectric materials

Ferroelectric oxides are a class of perovskite-type materials which exhibit spontaneous electrical polarization that can be oriented in the presence of an external electric field. Also, these materials possess other properties such as piezoelectricity and pyroelectricity and may have large dielectric constants which are important for actuator and sensor applications. BaTiO3 and Ba(ZrxTi1−x)O3 or Ba(Zr,Ti)O3 (BZT) are some of the most important ferroelectric oxides and, thus, will be covered in this review.

BaTiO3 single crystals

One of the biggest issues in the fabrication of the BaTiO3 single crystals lies in its hexagonal-tetragonal transition which occurs at 1430 °C and prevents the growth of a single crystal BaTiO3 from a stoichiometric melt. Although the BaTiO3 single crystal can be obtained from, for example, a BaTiO3–SrTiO3 congruent melt, or by the flux-method if the transition temperature is below 1430 °C, these methods are somewhat complicated. [71] In 1994, Yamamoto and Sakuma [71] reported that a single crystal of BaTiO3 can be grown via the SSCG method by utilizing the previously observed phenomenon of AGG in this type of material which occurs in the presence of a small excess of TiO2. The authors observed a non-uniform grain size distribution as well as AGG following annealing of the seeded ceramic compact at a temperature of 1300 °C. Although the size and quality of the single crystals could not be successfully controlled and there was a resulting high porosity, this study did show that SSCG could be a promising method for the fabrication of single crystals. A few years later, Yoo et al. [72, 73] reported growth of BaTiO3 single crystals without the presence of a seed crystal. The authors used previous observations in which BaTiO3 experienced AGG in the presence of a small amount of SiO2, which is similar to what Yamamoto and Sakuma [71] had used in their work. In their experimental work, Yoo and co-workers prepared an SiO2 slurry which they dropped on top of the surface of a polycrystalline green body of BaTiO3. This enabled the formation of the <111> fast-growing twin lamellae inside the polycrystalline BaTiO3 during sintering, which continued to grow without limitation. According to the authors, the structure of the twin lamellas of the BaTiO3 enabled easier grain growth when compared to two-dimensional nucleation. Also, they concluded that the formation of the twins was facilitated by the presence of liquid SiO2. The same authors also observed in [73] that there was greater success in forming single crystalline BaTiO3 in the presence of liquid SiO2 than in TiO2. Furthermore, Lee et al. [74] continued to investigate the AGG and formation of <111> twins of BaTiO3 in the presence of TiO2. The authors observed at temperatures higher than the eutectic (1360–1370 °C), a phenomenon which they called secondary abnormal grain growth (SAGG). According to them, the grains which experienced SAGG all contained twins, and, at the previously described temperature range, had grown without any limitation in size.

In their study on diffuse dielectric anomaly in BaTiO3, Kang and co-workers [75, 76] fabricated a BaTiO3 single crystal with <100> direction by the SSCG method. They obtained a single crystal that was entirely free of grain boundaries after sintering for 200 h at 1360 °C. Also, they showed that the single crystal had a significantly higher electrical conductivity compared to the ceramic BaTiO3 due to the absence of grain boundaries, which act as electrical barriers, and less oxygen vacancies, which have a direct influence on the diffuse dielectric anomaly.

Later on, Jung et al. [37] investigated grain growth behavior in BaTiO3 with a small excess of TiO2 during sintering in air with and without pre-sintering in H2 environment. The authors provided a theoretical explanation to the influence of the oxygen partial pressure on AGG. They explained that pre-sintering in H2 atmosphere for a long time led to an increase in the average grain size which in turn suppressed AGG during air sintering. In this way, the authors demonstrated that by increasing the initial average grain size in the polycrystalline matrix, it is possible to suppress AGG by reducing driving force for the growth of the faceted grains below the critical value.

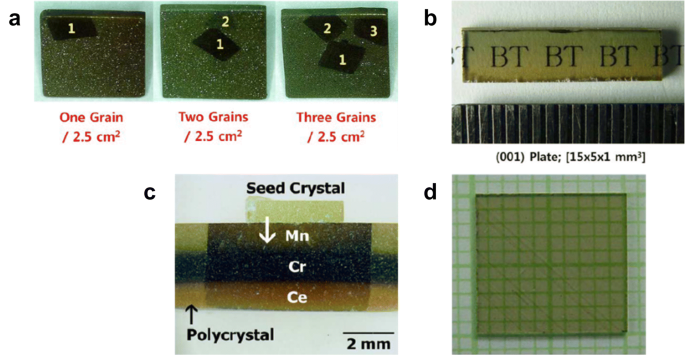

Although ferroelectric oxides such as BaTiO3 represent a very important group of materials with mainly electronic applications, there have not been many reports on SSCG of BaTiO3 single crystals recently. Most of the recent studies on SSCG of BaTiO3 were carried out by Ceracomp Co. which is now utilizing this method for the commercial production of BaTiO3 single crystals. In one of their publicly available technical reports [48], they mentioned that the number density of the abnormally grown grains in BaTiO3 can be controlled during the SSCG, thus implying that this method can be used for conversion of single crystals from polycrystalline ceramics (Fig. 12a). They also determined that this method can be utilized for the fabrication of transparent BaTiO3 single crystals (Fig. 12b) and even layered Mn-, Cr-, and Ce-doped BaTiO3 single crystals (Fig. 12c) with compositional gradients. In the same report [48], Lee presented the study on BaTiO3 single crystals obtained by the SSCG method doped with various ions (Ca, Ce, Zr, La, Nb, Nd, Cr, Co, Fe, Mg, and Mn). All these ions were successfully doped into BaTiO3 and then converted into a single crystal. Lee pointed out in his report that for obtaining high-quality transparent single crystals via the SSCG method, it is crucial to increase the density of the polycrystalline ceramics and reduce porosity before conversion of the single crystal, which can be done in a hot press (Fig. 12d).

SSCG growth of BaTiO3 single crystals: a control of the number density of abnormal grains; b transparent BaTiO3; c Mn-, Cr-, and Ce-doped BaTiO3 single crystal with compositional gradient; d highly dense transparent BaTiO3 single crystal obtained using a hot press [48]

BZT single crystals

Ba(Zr,Ti)O3 (BZT) polycrystalline ceramics have recently found a wide range of applications as piezoelectric materials, especially due to their lead-free nature and the environmental concerns which are imposed by the usage of lead-containing piezoelectric materials such as Pb(Zr,Ti)O3 (PZT). As it has been mentioned previously, single crystal materials show better dielectric, piezoelectric and many other properties compared to polycrystalline ceramics of the same composition. Therefore, development of technology which will be able to replace lead-containing ferroelectrics and piezoelectrics has become necessary.

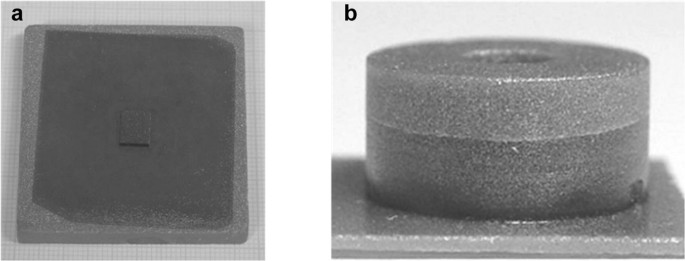

The addition of Zr in a BaTiO3 matrix was demonstrated to reduce the transition temperature from the cubic to tetragonal phases as well as increase the transition temperatures between the tetragonal and orthorhombic, and orthorhombic and rhombohedral phases. If the orthorhombic or rhombohedral phase is stabilized at room temperature, then the single crystal BZT shows good piezoelectric properties [47]. Due to their incongruent melting, BZT single crystals are hard to obtain by any conventional single crystal growth technique (flux, Bridgman, etc.). Therefore, SSCG method has been introduced as a promising technique for growth of high-quality BZT single crystals. In their study on the dielectric and piezoelectric properties of BZT single crystals, Lee and associates [77] were able to grow a rhombohedral BZT single crystal by the SSCG method. They prepared a single crystal by seeding a pre-sintered polycrystalline ceramic compact with a BaTiO3 seed crystal and sintering it for 100 h. Since the sintering and single crystal conversion were performed at temperatures lower than the melting temperature, a homogeneous chemical composition was obtained for the single crystal. Furthermore, the authors showed that the SSCG-grown <001> BZT single crystal had a piezoelectric charge constant which was more than six times higher and dielectric loss more than nine times smaller than the BZT polycrystalline ceramic, as well as an electromechanical coupling factor greater than of PZT ceramics.

In his earlier studies, Lee [47] also obtained BZT single crystals by seeding a BZT ceramic compact. He was able to observe an obvious boundary between a grown <100> single crystal with a size of (50 × 50 × 10) mm3 and polycrystalline matrix, as shown in Fig. 13a. Another thing Lee pointed out was that the SSCG method allowed for the fabrication of more complex shapes compared to the conventional single crystal growth techniques. One of the examples given by him is shown in Fig. 13b, which represents a ring-shaped single crystal obtained from a polycrystalline ceramic, which was uniaxially pressed, sintered, and later attached to a single crystal seed which enabled a single crystal conversion.

Growth of a <100> and b a ring-shaped BZT single crystal by SSCG method [47]

Al-based oxide materials

Al2O3 and MgAl2O4 single crystals

Polycrystalline alumina is an important industrial material that is used in various application, one of which being sodium vapor lamps [78]. Therefore, sintering this material is an important process for obtaining many different products. Fortunately, the majority of the problems associated with the usage of polycrystalline alumina can be overcome by instead using single crystal alumina, also known as sapphire.

The solid-state conversion of single crystals from polycrystals has appeared to be a promising technique which can be used for large-scale production of single crystal alumina. This method utilizes a well-known phenomenon that is related to AGG, which occurs in polycrystalline Al2O3 during heat treatment. Moreover, there are many reports which discuss other interesting phenomena in which AGG can be induced in the presence of CaO or SiO2 in alumina, or suppressed in the presence of MgO [79,80,81]. The effects of CaO and SiO2 in alumina can be explained by the formation of a liquid phase during sintering which acts as a driving force for grain growth through the formation of straight and faceted grain boundaries. On the other hand, the presence of MgO was observed to suppress AGG by coarsening of the grain boundaries. All of the aforementioned observations were later used in studies with the goal of developing a new approach for Al2O3 single crystal fabrication - SSCG.

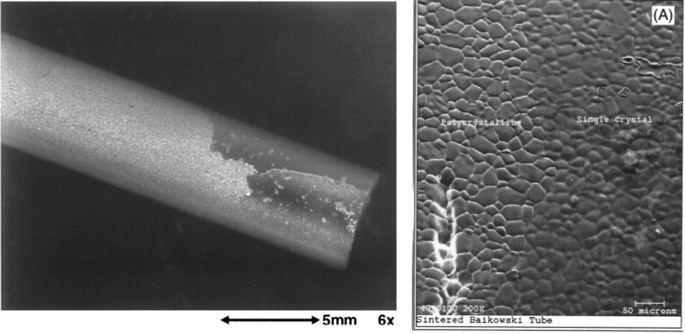

In one of the earliest studies, Scott et al. [80] investigated the possibility of the conversion of polycrystalline Al2O3 to single crystal sapphire without going through the melting process of the material. They sintered Al2O3 with an amount of MgO which was enough to suppress AGG during sintering. Once they allowed grains to grow up to 20–30 μm in average (NGG), through a careful control of the sintering temperature, they managed to instigate the AGG despite the presence of MgO in the matrix. The high temperature of 1880 °C which they applied was sufficient to promote AGG by inhibition of various dragging forces for boundary movement. They observed very high velocities of grain boundary migration which reached as high as 1 cm/h. As a result, the authors obtained a centimeter-sized single crystal sapphire converted from the polycrystalline Al2O3 (Fig. 14).

Single crystal sapphire grown by SSCG method: (left) large sapphire crystals grown at 1880 °C; (right) SEM micrograph of the interface between the polycrystalline Al2O3 matrix and the grown single crystal [80]

Similar to the previous study, Thompson et al. [81] investigated the influence of localized surface co-doping with SiO2 on the single crystal conversion of Al2O3. The co-doping with SiO2 was done prior to sintering, which enabled AGG and conversion of the polycrystalline matrix from the outside to the inside of the ceramic tube sample as soon as the heat treatment started (Fig. 15a, b). Their study demonstrated that it is indeed possible to obtain nearly transparent single crystals of Al2O3 by the SSCG method (Fig. 15c), with low porosity, high density, and good physical and optical properties. An interesting conclusion the authors made was that the SiO2 co-dopant did not directly affect the densification of the converted single crystal sapphire. In the early stages, SiO2 initiated conversion by removing the grain boundaries, which consequently provided a pathway for fast densification.

Optical micrographs of the single crystal Al2O3 (sapphire) grown via the SSCG method: a, b cross-section of single crystal sapphire grown from polycrystalline Al2O3; c translucent single crystal sapphire doped with MgO and SiO2 [81]

In the years that followed, through a series of studies on controlled AGG in alumina in presence of MgO, CaO and SiO2, Dillon and Harmer tried to explain the phenomenon of single crystal conversion. They proposed a mechanism of single crystal conversion via the SSCG method in alumina which involved rapid diffusion through an intergranular film of 10–20 nm thickness at the grain boundaries [82]. They also emphasized that the different grain boundary structures in alumina have a direct influence on the grain boundary kinetics, which they used to explain the conversion process [83,84,85].

While the previously mentioned authors investigated the SSCG of MgO-doped alumina by controlling AGG in the presence of SiO2 or CaO, the following authors utilized the SSCG approach to grow single crystals by the conversion of epitaxial film on substrates. The conversion of epitaxial films is a potential method for the fabrication of patterned single crystal substrates for various applications [86].

Park and Chan [87] reported their study on the epitaxial growth of single crystal alumina on a surface of sapphire which could be utilized to obtain a pristine sapphire surface when a high-quality surface finish is necessary (e.g. for substrate material for high-power blue LEDs and laser diodes). A thin film of Al was deposited by magnetron sputtering onto sapphire disks, after which a two-stage sintering was applied, first to oxidize the Al film at moderate temperatures and then to induce the growth of a single crystal at high temperatures by consumption of the oxide layer grains by the single crystal substrate. Furthermore, Browne et al. [88] conducted a somewhat similar investigation, but instead of single crystalline substrate, they used a polycrystalline MgAl2O4 spinel. This approach can be considered analogous to the SSCG method which has been discussed thus far. The authors used a wet-chemical method to prepare a sol-gel for spin-coating of the MgAl2O4 ceramic polycrystalline surface. After this step, the coated samples were heat-treated at different temperatures. The authors demonstrated that at 1400 °C, the coating was converted into an epitaxial layer by the growth of substrate grains and their corresponding absorption of the grains in the coating. A few years later, Dutta et al. [86] reported on a spin-coated sapphire substrate, which experienced a single crystal conversion of the coating to {0001} α-alumina (sapphire) following heat treatment in the range of 1100–1400 °C. During this heat treatment, the authors observed coarsening of the microstructure while retaining a higher level of porosity. But, a uniform conversion of the sol-gel coating was observed at the coating-sapphire interface.

YAG

After performing an extensive amount of research on materials with high laser performance, in 2007, Ikesue et al. [42] reported on the fabrication of Nd-doped yttrium aluminum garnet (YAG) single crystal (Nd:YAG) obtained through conversion from a polycrystalline material. The importance of Nd:YAG single crystals as laser materials has been covered elsewhere. The work of Ikesue has confirmed that it is possible to obtain a single crystal of high quality that is nearly pore-free using a fabrication method which is significantly different from conventional growth methods. The authors used a solid-state reaction method for the fabrication of an Nd:YAG polycrystalline powder, which was then pressed into a compact and sintered under vacuum. A seed crystal of YAG which was grown by the Cz method was placed on the top surface of the ceramic Nd:YAG and then sintered together in the range of 1700–1800 °C. This enabled the continuous growth of grains, which starts in the single crystal region and heads towards the polycrystalline grains. The authors observed abrupt abnormal grain growth at the single crystal-polycrystal interface, where the surface energy of the seed crystal was low enough compared to the surface energy of the polycrystals to consume the smaller polycrystalline grains. Continuous absorption of the smaller grains by the single crystal instigated a rapid grain boundary movement towards the rest of the polycrystalline region which at the end created a Nd:YAG single crystal.

A few years later, the influence of the different stoichiometries of Y2O3 and Al2O3 on the solid-state conversion of polycrystalline YAG to a single crystal was investigated by Bagayev et al. [89]. In their study, the authors used a <111> polished YAG single crystal as a seed crystal which they placed on the surface of the polycrystalline ceramic YAG. A micrograph of the thermally etched surface of the grown crystal which is entirely free of grain boundaries is shown in Fig. 16. The authors also observed that the single crystal growth rates were highly temperature dependent and were faster in samples with excess Al2O3. The highest achieved growth velocity was 0.15 mm/h. Additionally, the authors did not observe any differences in the growth rates between the Nd-doped and the undoped YAG.

Micrograph showing surface of the grown single crystal YAG by SSCG method [89]

Other oxide materials

Aside from Al-based oxides and YAG, there are also some reports on attempts to grow single crystalline materials of other oxide materials by the SSCG method. Such reports which investigated the feasibility of the growth of single crystals of the apatite-type of oxide ionic conductors were given by Nakayama et al. In 2013, they reported on the growth of single crystals of hexagonal apatite-type La9.33Si6O26 [90] by seeding with a single crystal of the same composition grown by the Cz method. As in the previous studies involving the SSCG method, the authors observed an abrupt motion of the grain boundary from the seed crystal with a low surface energy to a polycrystalline area with higher surface energy due to the seed crystal consuming the smaller, fine grains. In the same year, the authors reported on another study on apatite-type oxide La9.33Ge6O26 [91] grown as a single crystal by the SSCG method. Compared to the previous, La9.33Ge6O26 exhibited much less conductive anisotropy.

In 2016, Fisher et al. [92] reported on the growth of a BaFe12O19 single crystal via the SSCG method. The authors prepared the samples by cold isostatic pressing the polycrystalline powder with a seed crystal which was buried inside the powder compact, following heat treatment. The authors used a mixed control mechanism model of grain growth [23] to explain the single crystal conversion in the system being studied. They observed a significant temperature influence on the porosity of the grown BaFe12O19 single crystal as well as on the number of abnormally grown grains. Once the number of abnormal grains had become high, the growth of the single crystal stopped.

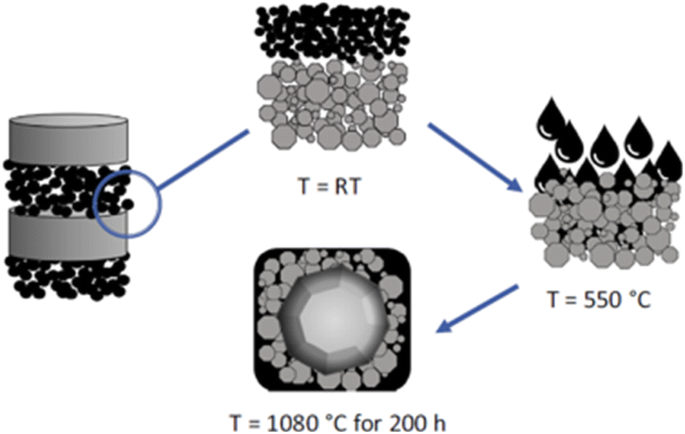

In more recent reports, Kappenberger et al. [93] reported on the growth of a single crystal LaFeAsO via the SSCG method. LaFeAsO belongs to the family of high temperature iron-based superconductors, which have considerable c-axis growth of the {1111} family of planes. This type of material is very difficult to obtain via conventionally used single crystal growth techniques such as the flux-method; therefore, the report of Kappenberger et al. has introduced a promising route for the fabrication of single crystals within this family of materials. The authors grew LaFeAsO single crystal from polycrystalline powder in the presence of a Na-As powder which turned into a liquid phase at around 550 °C during annealing, diffused into the pores of the polycrystalline compact and promoted crystal growth. A schematic representation of the steps for growth of LaFeAsO single crystals via the SSCG method is presented in Fig. 17. It was shown that this method is successful for obtaining large single crystals with considerable growth along the c-axis, with high quality as well as good physical properties.

Schematic showing SSCG process for obtaining LaFeAsO single crystals [93]

Mn–Zn ferrite

In literature, studies can also be found on the growth of single crystal ferrites via the SSCG. The earliest report, which dates back to 1985, was done by Tanji and associates [94]. Conventionally, Mn–Zn ferrites were produced via the Bridgman method. These were, therefore, costly and difficult to obtain. The authors applied the SSCG method, and by seeding the polycrystalline Mn–Zn ferrite matrix with the single crystal seed, they were able to successfully grow Mn–Zn ferrite single crystals. A few years later, a different group reported on a study regarding the same material, but, in comparison to the previous study, they tried to explain the influence of different sintering additives on single crystal conversion of Mn–Zn ferrite via the SSCG method [95]. The experiment was conducted by this group by adjoining two pieces of the polycrystalline ceramic to a single crystal seed from both sides with the assistance of ethyl silicate as an adhesive. After this step, they annealed the sandwiched samples in the N2–O2 atmosphere where they could observe AGG of the polycrystalline material which lead to single crystal conversion. Although the authors proved that the SSCG method can be used for the fabrication of Mn–Zn ferrites, the Bridgman method is still widely used [23].

Electric field-assisted single crystal growth